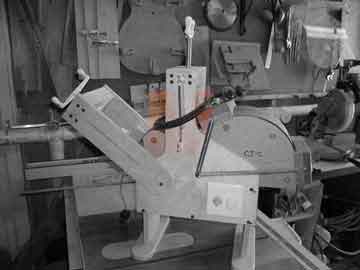

OK, I'll attempt to explain this. I'll assume that none of the plans use this design and that none of you have ever heard of it (I know I'm wrong, but that's how I'll attempt to go about explaining it. )

The first thing you'll need is a notch in all of you forms. Make it at the very apex of the waist curve and 1" deep by 1/4" wide.

This notch will accept the bar as it's lowered. This will allow the bar to be completely burried into the form thus allowing the caul to seat all the way into the curve. If you make the notches in the very apex of the curve and make a mark on what will be the very apex of the wood, this also serves as a registration system.

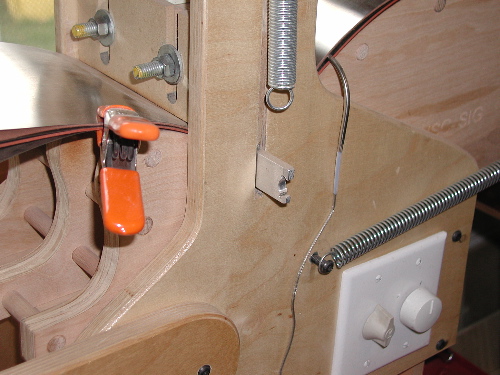

The bar itself is 1/4" by 1" piece of aluminum with some sort of notch in the ends to accept a spring. The spring is attached to the top of the tower and when hooked to the bar, applies counter pressure to the waist bend.

As you can see in the last photo, the spring is attached to the bar and the slats/blankets/ wood pack is pulled tight against the caul at the waist (it looks, in the photo, like there is a large gap but the pack is tight against the very center section of the caul).

This does two things: 1) allows you to position the pack with the waist line right where you want it, apply the spring tension and not worry about it slipping and giving you a bad bend as JJ just experienced. and 2) applies counter pressure at the apex of the bend, helping to prevent cracking at the waist.

I'm trying to work on a way to incorporate this into the cutaway tower but there are so many non-constant variables that it is very difficult to make it work.

Anything I missed?

|

.

.